Accompanied by Prof. Jan Wertel + Dr. res. med. Max Tönnemann

Bachelor PD

Michel

Bauer

I design at the intersection of traditional and emerging technologies. In 3D printing, I focus on process-optimized digital fabrication. My design approach is problem-driven, aiming for solutions that are both durable and high in quality.

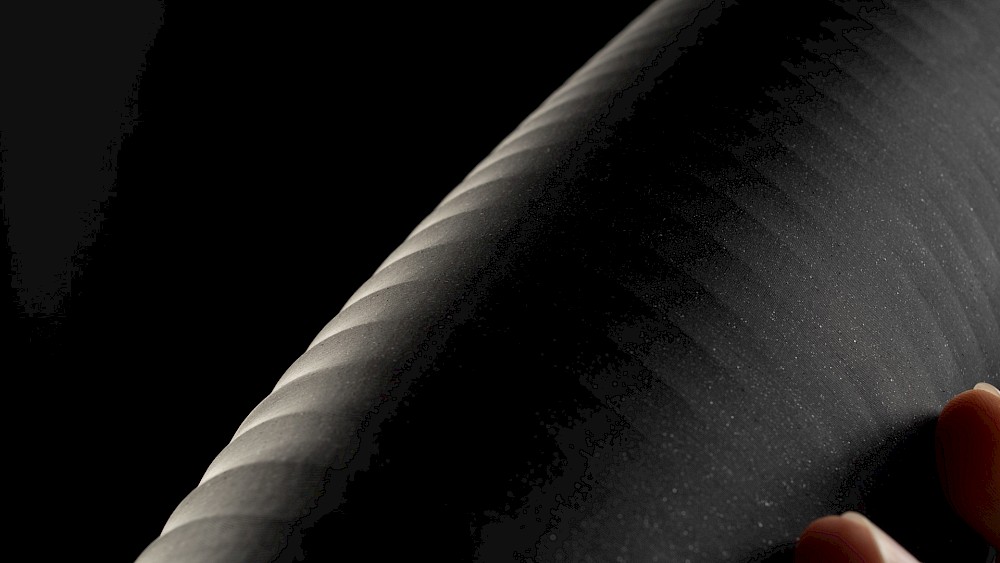

RapidProsthetics

Optimisation of additive manufacturing processes in arm prosthetics

What started with a visit to the 3D Center at the University Hospital Münster became our bachelor’s thesis and led to a new approach to rethinking forearm prosthetics. Using additive manufacturing methods like FFF and SLS, we aim to support and streamline the traditionally manual and time-consuming production process. Our goal is to make prosthetic care more personalized, efficient, and accessible.A key aspect of the project is our collaboration with orthopedic professionals. By partially automating production steps, we help reduce their workload and shorten waiting times. Based on scan data from technician-made molds, we digitally refine the design and 3D print all components – enabling precise, repeatable results with the opportunity for customization.Forearm prosthetics is a complex and often overlooked field. Despite lower demand than leg prosthetics, emotional and functional requirements are high. We see this as a valuable design challenge with real social relevance.

In cooperation with Isabelle Marit Schubert